Are you interested in diving into the world of industrial machine programming? Whether you’re a beginner or have some programming experience, our comprehensive course will equip you with the fundamental skills to excel in this field. Industrial machine programming is a specialized area that focuses on creating programs for industrial machines, such as PLCs (Programmable Logic Controllers), to automate various processes. This course is designed to provide a solid foundation in industrial machine programming, allowing you to confidently tackle programming tasks for a range of industrial automation applications.

During the course, you will be introduced to the basics of PLCs, including their hardware, wiring, and programming components. You will learn how to create PLC programs using Ladder Logic, one of the most commonly used programming languages in the industry. Through hands-on exercises and real-world examples, you will gain practical experience in designing and structuring programs to meet industry standards.

As part of the course, you will have access to industry-standard PLC programming software and a Live PLC Training Station. This will allow you to practice your programming skills in a simulated environment, giving you the confidence to apply your knowledge in real-world scenarios.

Key Takeaways:

- Gain a solid foundation in industrial machine programming

- Learn the basics of PLCs, including hardware and wiring

- Master Ladder Logic programming language for PLCs

- Develop programs that adhere to industry standards

- Practice your skills using industry-standard PLC programming software

What Is CNC Programming?

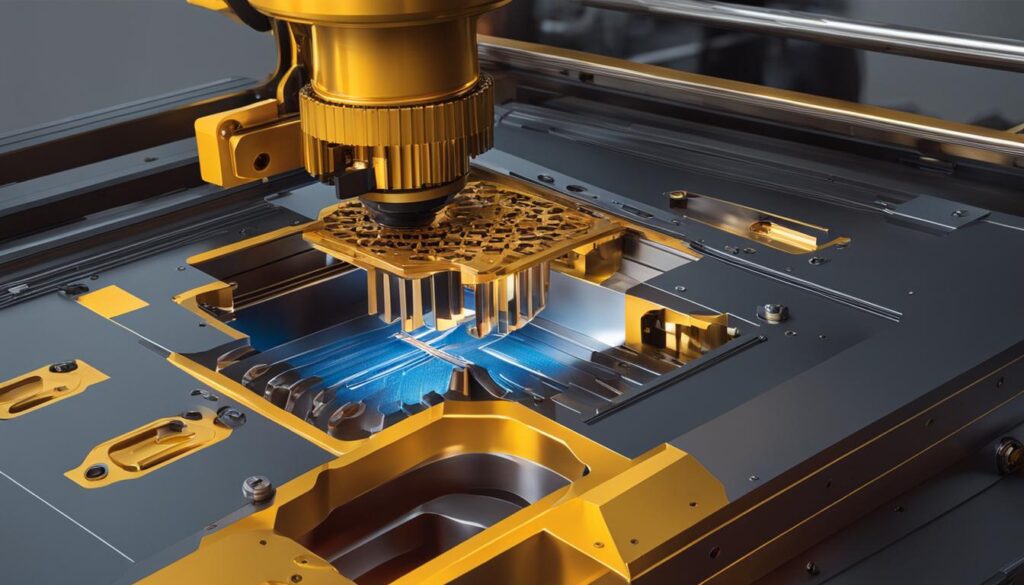

CNC programming is an essential aspect of modern manufacturing. It involves creating a set of instructions that control computer numerical control (CNC) machines to perform precise and complex tasks. CNC machines utilize computer-controlled movements and tools to shape and cut materials with utmost accuracy.

These machines rely on CNC programming to guide their movements and actions. The CNC programming language includes G-codes and M-codes, which are alphabetic and numeric codes that specify the machine’s actions, such as tool movements, speeds, and feed rates.

CNC programming enables manufacturers to achieve high levels of precision, complexity, and production volume compared to manual machining. These machines can perform intricate tasks with utmost accuracy, including milling, drilling, turning, and engraving. CNC machines are widely used in various industries, such as automotive, aerospace, electronics, and medical, to create components with tight tolerances and intricate designs.

To better understand the capabilities of CNC machines, here are some common types:

| Type of CNC Machine | Function |

|---|---|

| Lathes | Used to rotate the workpiece while a cutting tool shapes the material. |

| Milling Machines | Utilized for cutting and shaping the material by removing unwanted portions. |

| Laser Cutters | Employed for precision cutting of various materials using a high-powered laser beam |

| Plasma Cutters | Capable of cutting through electrically conductive materials using a plasma torch. |

CNC machines are also used in other applications like waterjet cutting and 3D printing, expanding their versatility and utility in the manufacturing field.

CNC programming plays a crucial role in the machining process, enabling manufacturers to perform intricate operations and achieve consistent and precise results. A deep understanding of CNC programming is essential for programmers and operators to optimize the performance of CNC machines and meet the demands of modern manufacturing.

Types of CNC Programming

When it comes to CNC programming, there are three main types that every aspiring programmer should know: manual programming, computer-aided manufacturing (CAM) programming, and conversational programming.

Manual Programming

Manual programming requires a deep understanding of how the CNC machine will respond to specific instructions. It involves directly inputting the programming codes to direct the machine’s movements and operations. This type of programming gives the programmer maximum control and flexibility but requires a high level of expertise.

CAM Programming

CAM programming, on the other hand, utilizes software to convert computer-aided designs (CAD) into CNC programming language. With CAM software, the programmer can generate the required codes automatically, minimizing human errors and speeding up the programming process. This type of programming is ideal for complex designs and intricate machining tasks.

Conversational Programming

Conversational programming is the most user-friendly option, particularly for beginners. It allows programmers to input instructions using plain language and easily understand the generated codes. This type of programming often comes with a user-friendly interface that simplifies the programming process, making it accessible to a wider audience.

Each type of CNC programming has its own advantages and is essential to know in the field of CNC machining. Programmers should choose the programming method that best suits their needs and the complexity of the machining tasks they are working on.

Learning CNC Programming

When it comes to learning CNC programming, there are various resources available for beginners. Whether you prefer online courses, books, or self-guided learning, you can find the right method that suits your needs. At the core of CNC programming is the ability to create computer-aided designs (CAD) using software like AutoCAD, SolidWorks, and Creo.

Understanding CAD software is crucial as it allows you to design and visualize the components and parts that will be manufactured using CNC machines. These software programs provide a user-friendly interface and a wide range of tools to create intricate and precise designs. Being proficient in CAD software will give you a head start in CNC programming.

Once you have your CAD designs ready, the next step is to convert them into CNC programming code. This is where computer-aided manufacturing (CAM) software comes into play. CAM software offers advanced features and algorithms that take your CAD designs and generate the necessary tool paths and G-code instructions for the CNC machine to execute.

There are several CAM software programs available, each with its own unique features and capabilities. Some popular choices include:

| CAM Software | Description |

|---|---|

| Mastercam | Industry-leading CAM software with a comprehensive set of features and excellent support. |

| SolidCAM | A CAM software integrated with SolidWorks, offering powerful milling and turning capabilities. |

| GibbsCAM | Known for its user-friendly interface and ease of use, suitable for beginners and experts alike. |

| CATIA | A powerful CAD/CAM software widely used in the aerospace and automotive industries. |

Even when using CAM software, having a good grasp of CNC programming fundamentals is essential. Understanding how your CAD designs are converted into CNC code allows you to troubleshoot issues, make optimizations, and have a deeper understanding of the machining process.

By leveraging the available learning resources and mastering CAD and CAM software, beginners can lay a solid foundation in CNC programming. With practice and dedication, you can unlock the full potential of CNC machining and bring your designs to life with unmatched precision and complexity.

Setting up for CNC Machining

Proper setup is crucial for successful CNC machining. Before starting, we need to ensure that the CNC machine setup is done correctly. Let’s go through the essential steps:

- Machine Cleanliness: It is crucial to begin with a clean machine to avoid any interference during the machining process. Clean the machine thoroughly, removing chips, coolant residue, and dust.

- Tool Alignment: Align the cutting tools according to the manufacturer’s guidelines. Proper alignment ensures accurate and precise machining.

- Workpiece Installation: Install the workpiece accurately, following the reference edges and faces. This ensures that the workpiece is properly secured and positioned for machining.

- Thermal Expansion: Warm up the machine before starting the actual machining process. This allows the machine to account for thermal expansion, ensuring consistent and accurate results.

- Tool Length Offsets: Set the tool length offsets to ensure that the machine accurately positions the cutting tools. This is important for achieving precise and consistent machining results.

- Calibrate Work Coordinates: Calibrate the machine’s work coordinates to establish accurate reference points for machining. This step ensures that the machine moves and positions the cutting tools correctly.

- Code Loading: Load the CNC program into the machine’s control system. The program contains the instructions for the machining process and ensures that the machine performs the desired operations.

- Coolant Check: Before starting the machining process, it is crucial to check the coolant system for proper flow. Adequate coolant flow helps in lubrication and cooling, improving machining efficiency and tool life.

- Test Runs: Perform test runs with and without a workpiece to ensure that the machine is operating as expected. This allows us to identify any issues or discrepancies before starting the actual production.

By following these steps, we can ensure a proper CNC machine setup, setting the foundation for accurate and efficient machining operations.

Safety and Troubleshooting in CNC Machining

In the world of CNC machining, safety should always be our top priority. To ensure a secure and efficient working environment, operators must adhere to proper safety protocols and actively monitor various aspects of the machining process. Let’s take a closer look at some essential safety measures and troubleshooting techniques in CNC machining.

1. Machine Monitoring

Constant machine monitoring is crucial for identifying any potential issues and preventing accidents. Operators should pay close attention to the cutting tools, listening for any unusual sounds or vibrations that might indicate a problem. By staying vigilant, we can detect and address issues before they escalate.

2. Visual Inspection

Visual inspection plays a vital role in ensuring the quality of the machining process. After each workpiece, it is essential to conduct a thorough visual inspection to identify any imperfections or defects. By doing so, we can make necessary adjustments to maintain high standards of quality and precision.

3. Tooling Quality

The quality of tooling used in CNC machining directly impacts the accuracy, precision, and surface finish of the final product. It is crucial to invest in high-quality cutting tools that can withstand the demands of the machining process. By using reliable tooling, we minimize the risk of tool breakage and maximize overall performance.

4. Stable Power Supply

A stable and consistent power supply is essential for the uninterrupted operation of CNC machines. Ideally, a 3-phase power supply should be in place to ensure steady power delivery. By maintaining a stable power supply, we can mitigate the risk of sudden machine shutdowns and potential damage to the workpiece or equipment.

By prioritizing safety and implementing effective troubleshooting techniques, we create a secure and productive CNC machining environment. Remember to follow safety guidelines, conduct regular visual inspections, invest in quality tooling, and ensure a stable power supply. These measures contribute to the overall success and efficiency of CNC machining operations.

Conclusion

In conclusion, CNC machining is a fascinating field that offers beginners the opportunity to delve into precise and intricate metalworking processes. By starting with a solid foundation in CNC programming and familiarizing themselves with CAD and CAM software, beginners can gain the necessary skills to operate CNC machines effectively. It is crucial to understand the setup procedures and safety measures involved in CNC machining to ensure smooth and successful operations.

Fortunately, there is a wealth of learning resources available for beginners. Online courses, books, and tutorial videos are valuable tools for acquiring knowledge and practical skills in CNC machining. These resources provide step-by-step guidance and insights from industry experts, enabling beginners to progress at their own pace. Additionally, seeking assistance from knowledgeable individuals when faced with challenges can greatly aid in the learning process.

As beginners continue to learn and practice CNC machining, they will unlock the vast possibilities that this discipline offers. With dedication and perseverance, they can master the art of CNC machining and explore its applications in various industries. Whether it’s creating intricate metal parts or fabricating complex prototypes, CNC machining empowers beginners to bring their creative ideas to life with precision and accuracy.

FAQ

What will I learn in the industrial machine programming course for novices?

By the end of this course, you will understand the basics of PLCs, including hardware, wiring, and programming components. You will learn to create PLC programs using Ladder Logic and common routines. The course covers commonly used programming instructions, program design, and structure, and emphasizes creating programs to industry standards. You will have access to real PLC programming software and a Live PLC Training Station for hands-on practice.

What is CNC programming?

CNC programming is an essential aspect of modern manufacturing. It involves creating a set of instructions that control computer-controlled machines to perform precise and complex tasks. CNC machines use G-codes and M-codes to control the machining process. CNC programming enables high levels of precision, complexity, and production volume compared to manual machining. CNC machines include lathes, milling machines, laser cutters, plasma cutters, waterjet cutters, and 3D printers.

What are the types of CNC programming?

There are three main types of CNC programming – manual, computer-aided manufacturing (CAM), and conversational. Manual programming requires the programmer to have a deep understanding of how the machine will respond. CAM programming uses software to convert CAD designs into CNC programming language. Conversational programming is the easiest type of programming for beginners and allows users to enter essential details in simple language. All three types have their advantages and are essential to know.

How can I learn CNC programming as a beginner?

Beginners can learn CNC programming through online courses, books, and self-guided resources. It is important to familiarize yourself with CAD software, such as AutoCAD, SolidWorks, and Creo, as it is used to create computer-aided designs. CAM software is crucial for converting CAD designs into CNC programming code. There are various CAM software programs available, including Mastercam, SolidCAM, GibbsCAM, and CATIA. It is helpful to have a good grasp of CNC programming even when using CAM software.

What is the setup process for CNC machining?

Proper setup is crucial for successful CNC machining. Before starting, ensure the machine is clean and free from chips, coolant residue, and dust. Align and load the cutting tools according to manufacturer guidelines. Warm up the machine to account for thermal expansion. Set tool length offsets and calibrate the machine’s work coordinates. Install the workpiece accurately using reference edges and faces. Load the CNC program and check the coolant for proper flow. Finally, perform test runs with and without a workpiece.

What safety measures should I take in CNC machining?

Safety is important in CNC machining. Operators should monitor the cutting tools, listen for unusual sounds, and keep an eye on coolant flow and temperatures. If any issues arise, such as smoke or burning smells, the machine should be shut down immediately. Visual inspections should be conducted after each workpiece to identify any imperfections. High-quality tooling should be used to maximize accuracy, precision, and surface finish and reduce the risk of tool breakage. A stable and consistent power supply, ideally 3-phase, is crucial for CNC machines.

How can beginners progress in CNC machining?

CNC machining is an exciting discipline that offers precise and complex metalworking capabilities. Beginners can start by learning the basics of CNC programming, familiarizing themselves with CAD and CAM software, and understanding the setup and safety measures for CNC machines. There are various learning resources available, including online courses, books, and tutorial videos. By practicing and seeking help when needed, beginners can progress in CNC machining and explore its vast possibilities.